BLOG: Bulk vs. Rack? How We Decide the Right Method of Storage for our Clients

By Sean Fox, Marketing and Communications Manager

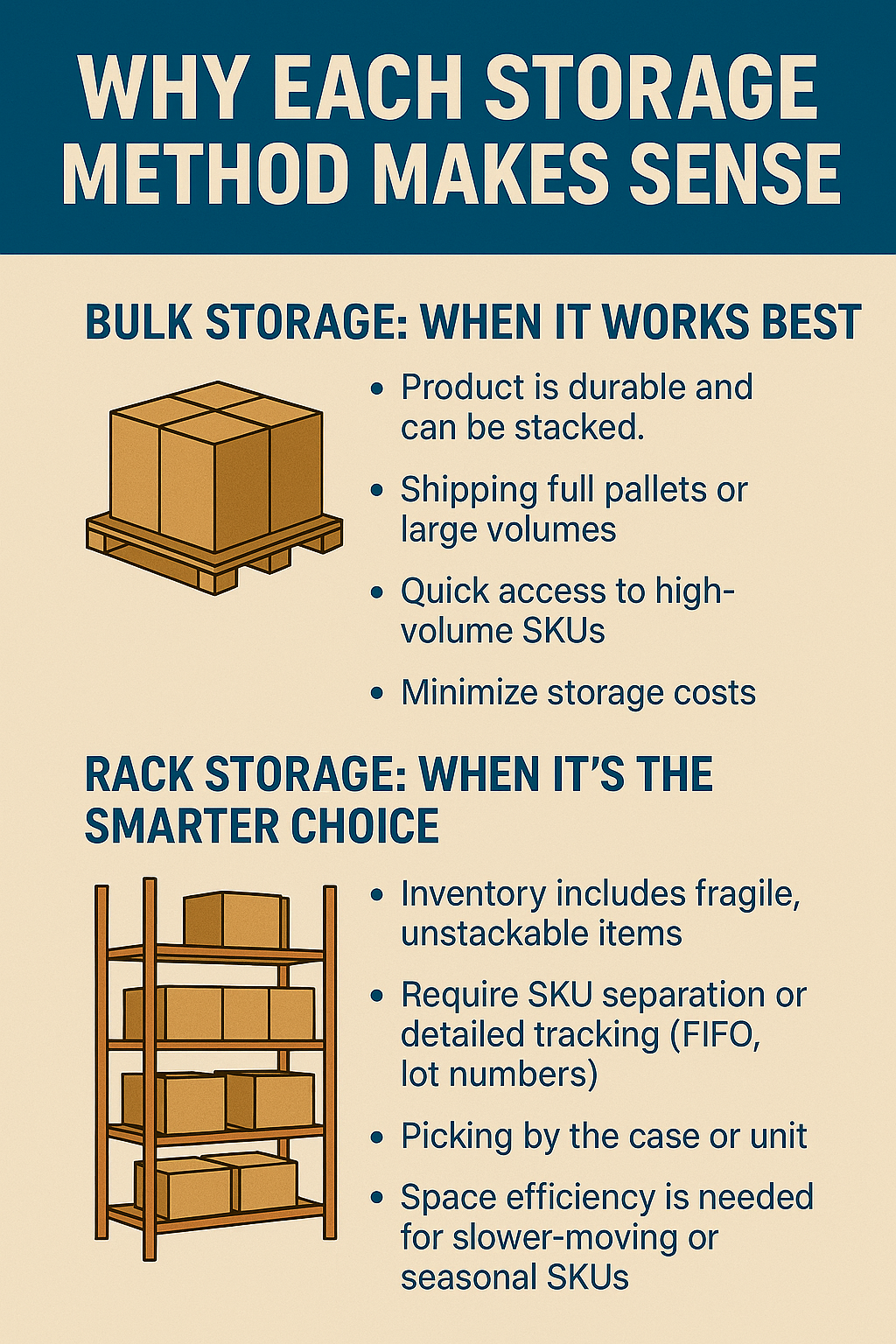

When working with companies to create warehousing solutions, one of the most important decisions we must make is where inventory should live—in bulk storage or in racking. Bulk vs. Rack? This choice directly impacts storage costs, picking speed, and overall efficiency, so we want to make sure we get it right. I thought it would be helpful to give a peek behind the scenes at how we make this decision—and why each method makes sense depending on product types and operations.

What Is Bulk vs. Rack Storage?

Bulk Storage: Pallets are stored directly on the floor, often stacked if product type allows. There’s no shelving or racking—just organized floor space that can be manipulated based on the need. Currently, we have over 585,000 sq. ft. of bulk space across our network in ambient and temp-controlled environments.

Rack Storage: Inventory is stored on industrial shelving (pallet racking), with multiple levels to take advantage of vertical space and the ability to add in or take out crossbeams as needed. Currently, we have over 59,000 rack locations across our network in ambient, temp-controlled, and hazardous environments.

Key Questions We Ask

1. Can the product be stacked safely?

- If product can be stacked two or more pallets high without damage, bulk storage is a good option. It allows us to maximize floor space without investing in racking.

- If product is fragile, non-stackable, or has specific handling requirements, we like to place it in the racks to ensure safety and accessibility.

2. What are the pallet dimensions, specifically width, depth, and height?

- For rack, we like to stay within standard pallet dimensions of 40-inch width, 48-inch depth, and 58-inch max height. This allows us to maximize the racking environment that can go up to five or six high at some locations.

- For bulk, it’s better suited for oversize pallets that can get up to 96 inches or greater. It is also better for heavy or oddly shaped items that rack wouldn’t be able to accommodate.

3. Will we be picking full pallets, cases, or individual units?

- If picking full pallets, bulk storage is going to be a faster and more efficient way to go. There’s even the possibility of picking multiple pallets at a time if you have the right equipment.

- If inventory requires case or each picking, rack storage allows for better organization and easier access to individual SKUs. In some situations, we can even create unique locations for certain types of picking (pallet vs. case, for example).

4. Are there FIFO or lot control requirements?

- When you need First-In, First-Out (FIFO) or LOT control capabilities, rack storage offers better visibility and easier rotation. We can clearly identify and access the oldest stock first when picking.

- For products where FIFO isn’t critical and there are no lot control requirements, bulk storage can be more cost-effective as we are able to store pallets in deeper rows where it doesn’t matter which pallet is picked for an order.

At the end of the day, the key is aligning the storage strategy with operational needs. Our ultimate goal is always the same: get product stored in the most efficient, cost-effective way possible—without sacrificing speed, accuracy, or safety.

Looking for help on how to best store your inventory? Reach out—we’d be happy to walk you through a storage assessment and see what capacity in our network we have available. Click HERE to contact us!